121 Seaport Boulevard

PROJECT DETAILS

This Class-A office building was designed to accommodate a challenging site while promoting sustainability and emphasizing the neighborhood’s innovative aesthetic in Boston’s Seaport District. The structure’s elliptical shape creates an open concept with minimal columns and floor-to-ceiling glass windows. The superstructure was built from the top down, while the underground parking garage was simultaneously excavated. This added to the design challenge, but ultimately saved millions of dollars and six months of schedule.

Location:

Boston, Massachusetts

Year:

2016

Customer:

Cives Steel CO. New England

Owner:

Skanska USA Commercial Development Inc

Architects:

CBT Architects

Engineers:

McNamara Salvia Structural Engineers

General Contractor:

Skanska USA Building, Inc.

Steel fabricators:

Cives Steel CO. New England

CSC Products Used in Completing this Project

square of LF2 composite floor deck

square of LF3 composite floor deck

square of NS Roof deck

tons of joists; 22” and 30” long span composite joists

The 17-story, 440,000 square foot building located at 121 Seaport Boulevard, features a three-story lobby, dedicated fitness center, views of the harbor and skyline, and wide-open office space to meet the changing demands for commercial office layouts.

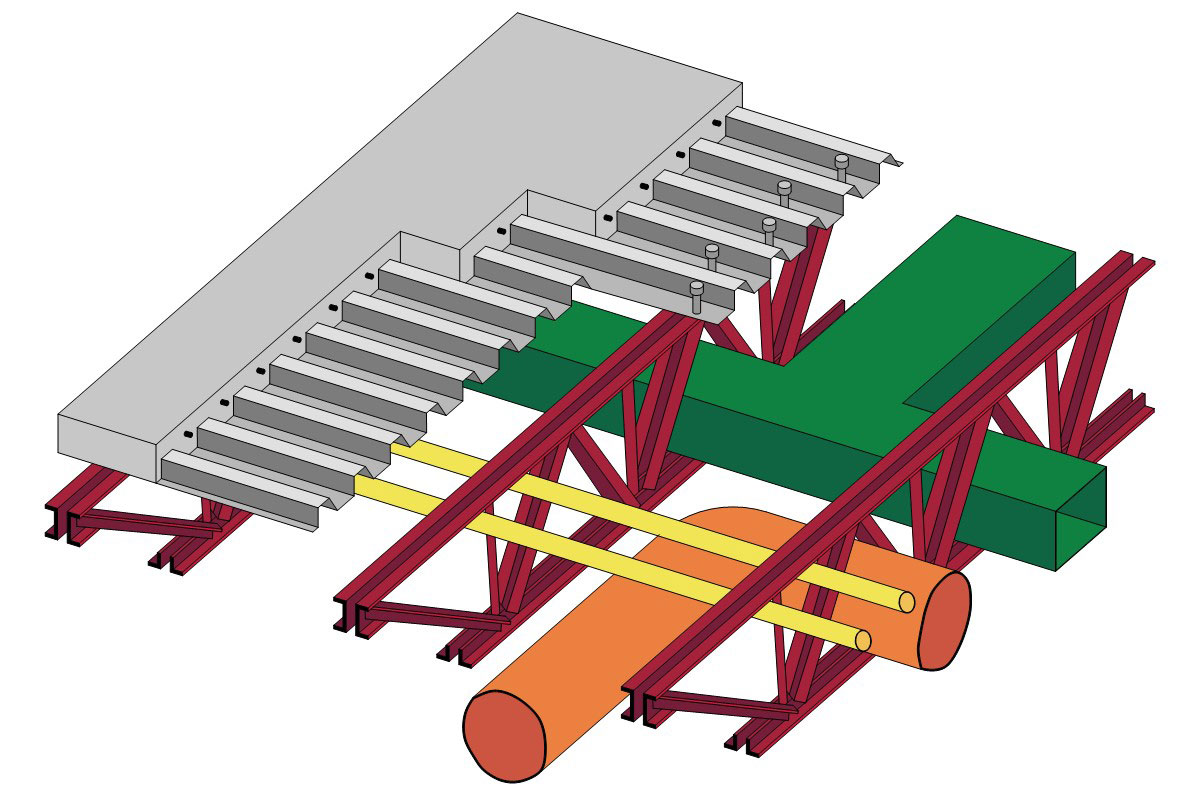

At the core of this beautiful building are CJ-Series composite steel joists, which support the composite steel deck and the concrete slab poured on top. Composite steel joists offer several advantages compared to composite beams. The open web steel joists can span long distances to create wide-open spaces. At the same time, they offer an excellent span-to weight ratio, which decreases the overall weight and cost of the steel structure.

The efficient design reduces the overall amount of materials required, making the construction process faster. Minimizing the joist count also reduces the amount of spray fireproofing that must be done to achieve the required fire rating for the floors. The open web construction of the joists allows MEP trades to run plumbing, electrical, and mechanical equipment through the joists rather than under the beams. This minimizes the overall floor depth, maximizes ceiling heights, and/or reduces overall building height.