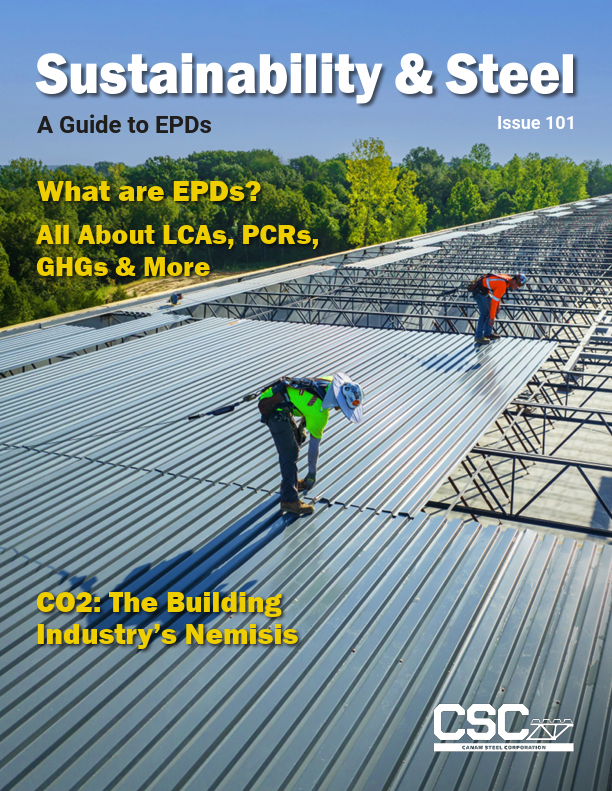

Sustainability

Committed to Steel Manufacturing Sustainability

Doing Our Part to Protect the Environment

At CSC, our commitment to environmental stewardship, community engagement, and employee well-being is at the heart of everything we do. This dedication is evident in our manufacturing and construction practices. We engineer products using responsibly sourced steel and implement measures to minimize waste and pollution in our production facilities. Our holistic, integrated approach ensures we achieve balance within both our external and internal environments.

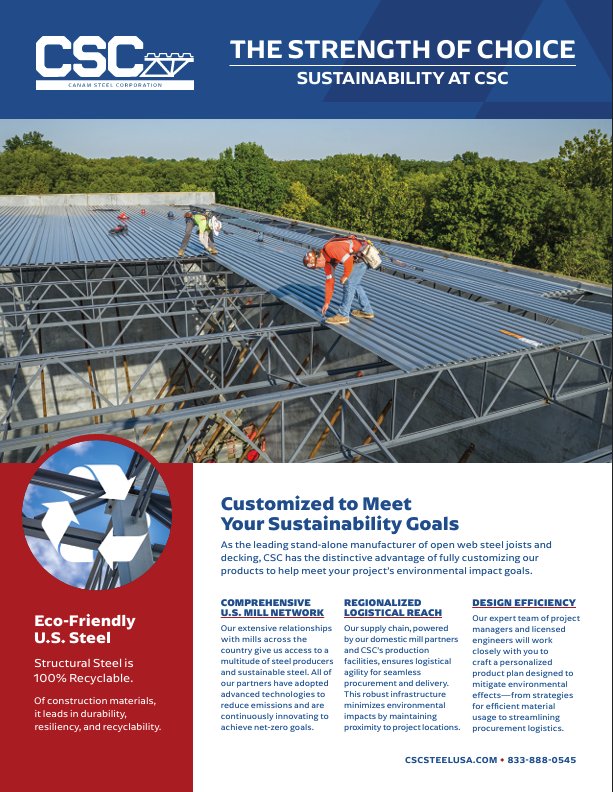

The Strength of Choice

Customized Steel Products to Meet Your Sustainability Goals

As the premier manufacturer of open-web steel joists and decking, CSC offers unparalleled customization to meet your project’s environmental impact goals. Our high-quality, expertly engineered products are crafted from responsibly produced steel sourced from leading American suppliers dedicated to carbon reduction and achieving carbon-zero targets. At CSC, we continuously refine our processes to enhance systems and minimize environmental impact.

Comprehensive U.S. Steel Mill Network

Our strong partnerships with steel mills nationwide provide access to a diverse array of sustainable steel options. With expert guidance from our team, customers can evaluate and select steel based on criteria such as CO2 emission levels, mill location, and cost. Our steel producer partners leverage advanced technologies to reduce emissions and continuously innovate to achieve net-zero goals.

Localized Supply Chain for Efficient Logistics

Transporting raw materials and finished steel products over long distances can significantly increase energy consumption and harmful emissions. CSC’s robust supply chain, supported by our extensive network of domestic mill partners and fabrication plants, minimizes environmental impacts by maintaining proximity to project locations.

Creating Design Efficiencies

CSC’s products are custom engineered and manufactured to meet your project’s unique budget and requirements, adhering to our high-quality standards. When an order is placed, a dedicated CSC project manager, engineer, and drafter are assigned to oversee each project.

Collaborating with CSC experts from the early conceptual phase allows us to recommend ways to balance sustainability objectives, schedule demands, and product costs. Our skilled team of project managers and licensed engineers will work closely with you to develop a personalized product plan designed to mitigate environmental impacts, from efficient material usage strategies to streamlined procurement logistics.

Our Community

Our commitment to sustainability extends beyond environmental practices. At CSC, we implement Environmental, Social & Governance (ESG) practices that prioritize environmental and social issues alongside responsible corporate governance, taking a holistic approach to sustainability and stewardship.

Within our plants and surrounding communities, we are dedicated to ensuring the safety and well-being of our employees, customers, and neighbors. By fostering a culture that emphasizes the interdependence of environment, health, and safety (EHS), we proactively address environmental responsibility, illness reduction, and injury prevention. Our commitment to our communities is further demonstrated through various philanthropic efforts, including volunteering and charitable activities.

Learn more about our commitment to our employees and community on our Community page.

Resources

Industry Partnerships

CSC actively supports industry-wide sustainability efforts and initiatives through memberships with the following organizations:

Environmental Product Declarations (EPDs)

Similar to food nutrition labels, Environmental Product Declarations (EPDs) offer objective, third-party verified reports detailing a product’s environmental impact throughout its life cycle. These reports provide metrics on indicators such as global warming, ozone depletion, and smog formation. EPD data is integrated into various codes, standards, and rating systems, including green building rating systems like LEED and Living Building Challenge.

CSC can produce EPD reports upon request for each of our plants, offering transparent, empirical insights into our products. Additionally, CSC can now generate project-specific EPDs, which consider the mill source and project location for enhanced transparency.