Composite Floor System for Multi-Story Structures

Since 1982, the Vescom Composite Floor System has been installed on hundreds of projects across North America for all types of multi-story residential, institutional, healthcare, and commercial buildings.

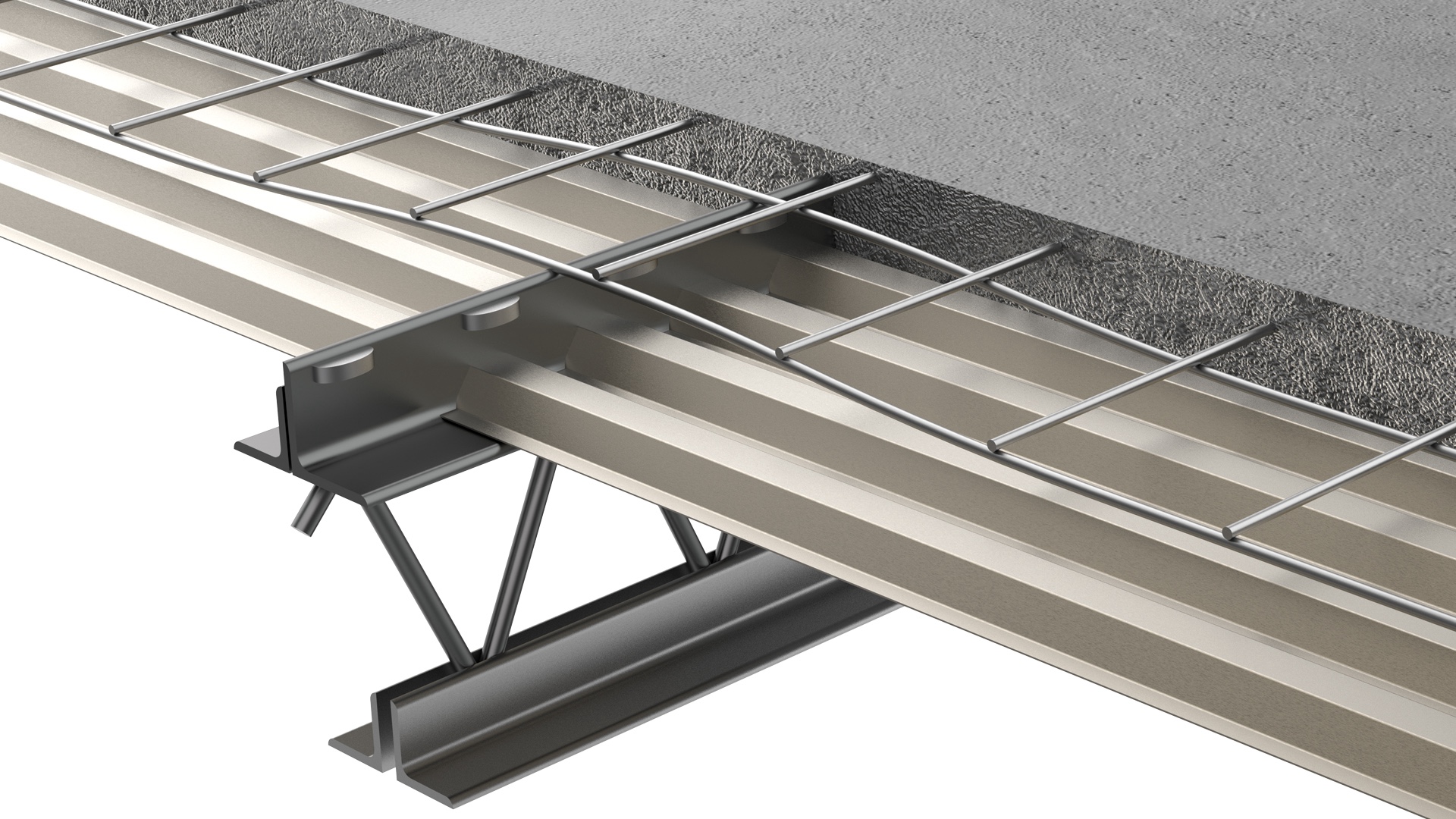

Vescom’s inverted top chord was developed to form a mechanical bond with the concrete slab through its embossed vertical leg. This allows Vescom to differentiate from competitors and offer a simpler solution.

This unique design creates a superior lateral diaphragm action resulting in less deflection, vibration, and bounce plus greater stiffness, making it the superior composite floor system in the industry.

Engineered for Speed, Strength, and Safety

Vescom offers outstanding structural performance with its unique mechanical connection between the joist and concrete, setting it apart in the market. The single structural floor system offers quality, affordability, and versatility.

Vescom is the preferred floor system for:

- Senior Living and Nursing Homes

- Apartment Buildings

- Condominiums

- Student Housing

- Hotels and Resorts

- Medical Facilities

- Office Buildings

- And Many Other Structures

Learn More About The Vescom Advantage

- Cost-Saving Design

- Top Industry Fire Ratings

- Acoustical Considerations

- Effortless Installation

- Adaptability & Flexibility

- Composite Design

- Adaptable Design Possibilities

- Design Support Made Simple

Quick & Easy Installation

The Vescom installation process emphasizes both speed and efficiency by using fewer components and less manpower than other floor systems. No scaffolding, bridging or temporary supporting members are required, and all work is done from above as the erection crew lays its own working platform.

Vescom’s Simple Erection Process

- Bays are framed with steel or walls, and bundles of joists are placed.

- Joists are spread to the required spacing–no bridging required.

- Pre-cut decking is easily placed between joists.

- Decking is attached by shot pins, screws, or welding.

- Mesh is rolled into place. The unique top chord design eliminates the need for high chairs.

- Concrete is placed.

No stripping of forms or removal of system components needed. The metal deck is a permanent form!

Partner with CSC on your next project

Our relationship with CSC is phenomenal, it's a team, it truly is a team. We're pulling from the same side of the rope.

PROJECT MANAGER

Ira G Steffy & Son